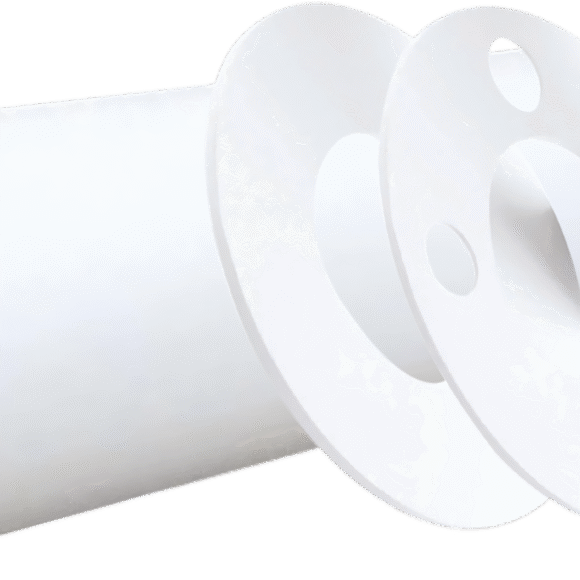

Expanded PTFE (ePTFE) is a high-performance sealing material derived from polytetrafluoroethylene (PTFE), engineered into a microporous structure through a special stretching process. It is widely used in sealing applications where chemical resistance, temperature tolerance, and long service life are critical.

Expanded PTFE gasket sheets offer excellent compressibility and are chemically inert, making them ideal for use in applications with irregular surfaces or low bolt load.

• Material: Expanded PTFE

• Temperature Range: -200°C to 260°C

• Pressure Resistance: Up to 20 MPa

• pH Range: 0 – 14

Availability: In Stock

Suitable for food processing, chemical processing, and pharmaceutical industries.

• High compressibility

• Chemically inert

• Suitable for low bolt load applications

2. Lined and Glass-lined Equipment:

3. Manways, Heat Exchangers, Pumps, Valves:

4. Aggressive Chemical Services:

5. Oxygen and Chlorine Services:

6. Food and Pharma Applications:

1. Material & Performance Standards:

2.Application Standards:

3. Fire Safety:

| Feature | ePTFE | Conventional PTFE | Compressed Fiber | Rubber Gaskets |

|---|---|---|---|---|

| Sealing on irregular surfaces | Excellent | Poor | Moderate | Poor |

| Chemical resistance | Excellent | Excellent | Moderate | Poor |

| Temperature range | -268°C to +260°C | Similar | Lower | Lower |

| Creep & cold flow | Low | High | Low | Moderate |

| Reusability | Possible (in some cases) | Poor | Poor | Poor |

| Conformability | High | Low | Moderate | High |

| Installation | Easy, no torque retightening | Needs care | Requires torque | Easy |

| FDA/Pharma compliant | Yes (grades available) | Yes | No | No |

Reviews

There are no reviews yet.